Grasping RainierGPR Concrete Scanning: Essential Tips and Tricks

Grasping RainierGPR Concrete Scanning: Essential Tips and Tricks

Blog Article

Harness the Strategic Side of Concrete Scanning for Unparalleled Job Success and Quality Control

In the world of modern construction and facilities advancement, the application of concrete scanning technology has arised as a crucial tool for guaranteeing job success and preserving top quality criteria. The true power of concrete scanning lies not only in its capacity to improve job end results but additionally in its capacity to change traditional practices, setting a new benchmark for accuracy and efficiency in the building market.

The Value of Concrete Scanning

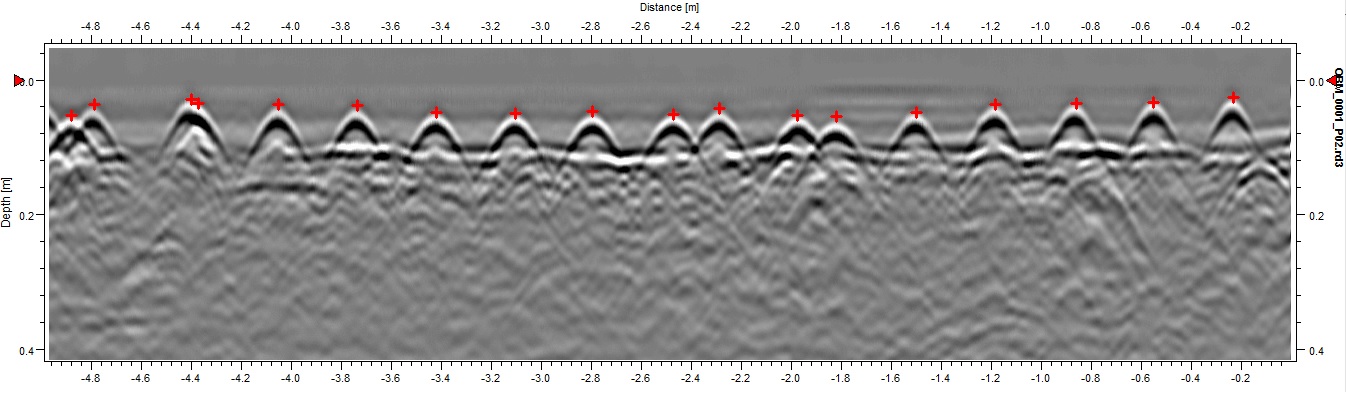

Concrete scanning is an essential action in construction projects to ensure the safety and integrity of frameworks. By making use of numerous scanning technologies such as Ground Permeating Radar (GPR) and electromagnetic induction, construction teams can non-destructively evaluate the subsurface of concrete frameworks to recognize possible hazards like rebar, avenues, or post-tension wires. This details is vital for job designers, service providers, and managers to make educated decisions and stay clear of expensive blunders throughout the building procedure.

Among the main reasons why concrete scanning is so essential is its capability to stop crashes and injuries on the building site. Accidentally reducing through a real-time electrical channel or damaging post-tension cords can have disastrous consequences, not just in terms of security yet likewise in terms of project delays and financial ramifications. By performing detailed concrete scanning before any kind of drilling, reducing, or coring tasks, building groups can mitigate dangers and develop a safer working setting for everyone involved.

In enhancement to safety factors to consider, concrete scanning likewise plays a crucial duty in ensuring the long-lasting toughness and top quality of the structure. By discovering any kind of anomalies or flaws hidden underneath the surface area, such as gaps or delamination, very early treatment can be implemented to deal with these problems prior to they rise right into even more significant issues. Inevitably, spending in concrete scanning is an aggressive measure that can save time, money, and resources over time, while additionally supporting the greatest requirements of building excellence.

Advanced Innovation for Specific Results

Furthermore, 3D scanning modern technologies offer a detailed sight of the subsurface environment by creating in-depth electronic versions. These versions provide valuable understandings right into the structural stability of concrete elements and assist in recognizing possible weak points prior to they escalate into significant concerns. By including these advanced innovations into concrete scanning methods, building and construction groups can streamline workflows, decrease job delays, and make sure the total top quality and success of the task. The accuracy and efficiency offered by these tools add considerably to the job's success by helping with notified developing and decision-making quality control actions.

Enhancing Job Efficiency and Timelines

In addition, concrete scanning allows groups to recognize possible threats and architectural weak points early, enabling timely remediation and stopping mishaps that could hinder project timelines. The real-time data provided by scanning devices promotes educated decision-making, causing smoother sychronisation among various professions and stakeholders. This boosted cooperation decreases problems, enhances efficiency, and ultimately increases job shipment.

Moreover, by proactively addressing concerns with concrete scanning, building and construction groups can abide by schedules better, minimize downtime, and enhance resource appropriation. The capability to identify covert challenges and verify architectural stability efficiently adds to discover here overall project performance and timelines, making certain effective outcomes and client satisfaction.

Ensuring Safety And Security and Danger Mitigation

Threat reduction techniques can be boosted with the comprehensive details provided by concrete scanning, allowing task teams to make enlightened decisions that reduce the likelihood of unexpected incidents. In addition, by accurately drawing up subsurface problems, contractors can prevent expensive rework, delays, and damages to existing frameworks, additionally adding to overall project safety and success. Executing concrete scanning as a regular method not just makes certain a safer workplace but additionally infuses self-confidence in stakeholders relating to the task's dedication to top quality and risk monitoring.

Quality Control Through Concrete Scanning

Concrete scanning plays a critical role in maintaining quality control criteria within building jobs. By utilizing advanced scanning modern technologies such as Ground Penetrating Radar (GPR) and Concrete X-ray, task managers and designers can make sure the honesty and high quality of concrete frameworks. With concrete scanning, prospective defects, such as voids, splits, or strengthening bar congestion, can be found non-destructively, enabling for Learn More prompt interventions to keep the architectural integrity of the job.

Quality control via concrete scanning not only helps in recognizing existing concerns but likewise enables aggressive steps to prevent future problems that might jeopardize the safety and longevity of the framework. By conducting comprehensive scans at essential phases of building and construction, teams can verify the accuracy of architectural plans, confirm the positioning of essential aspects, and address any type of discrepancies without delay. This positive strategy lessens rework, decreases pricey delays, and inevitably leads to the delivery of high-quality, durable frameworks that surpass or meet industry criteria.

Final Thought

In conclusion, concrete scanning plays an essential function in making sure job success, security, high quality, and efficiency assurance. The tactical side supplied by concrete scanning enables for aggressive threat reduction and boosts total project monitoring.

In the realm of modern-day construction and facilities advancement, the utilization of concrete scanning technology has arised as an essential tool for making certain job success and maintaining top quality requirements. By incorporating these advanced technologies into concrete scanning techniques, building and construction groups can improve operations, minimize job delays, and ensure the general high quality and success of the job.Given the crucial nature of job performance and timelines in building management, the emphasis currently shifts in the direction of ensuring safety and security and mitigating risks within the task atmosphere.Concrete scanning plays a critical duty in supporting quality guarantee standards within construction projects. By using innovative scanning technologies such as Ground Penetrating Radar (GPR) and Concrete X-ray, task supervisors and designers can make sure the honesty and quality of concrete frameworks.

Report this page